Three Point Hitch Small Tractor Log Skidder Attachment “Hook Up and Go”

Hook Up an Go

Whether managing a woodlot, forest tract, or hobby farm, small-parcel landowners are perpetually on the move. They need effective tools to help manage their valuable timber resource-for timber maintenance, pre-commercial thinning, low-impact logging, firewood production, or wildfire fuel reduction. Based on his experience managing a family farm, Tom Repko of Small Wood Lot Tools in Dallas, Oregon designs and builds the Timber Talons attachment. Specifically, he aims to build equipment that is easy to use and maintain in his own cost-sensitive operation. Though he started out building equipment for him-self, others quickly took interest. Repko’s farm in the rolling hills of western Oregon comprises 40 acres of oak savan-nah and 15- to 30-year-old Douglas fir in dense patches. It’s a one-man operation. The property is clean and well managed.

He predominantly cuts firewood and his only commercial logging so far has involved clearing windfall. “I’m not a logger and I don’t want to cut the oak,” he said. “I’m constantly cleaning up the woods and I’m maintaining the firs for future logging. I do all my own thinning and limbing, and I’m just starting my first pre-commercial thin. I may make a couple of loads of logs from that, but most will be used for firewood.” Working alone, Repko knew that he needed a safe and effective way to pull downed leaners and yard trees out to his roads. And he wanted to stay out of the poison oak and blackberries. “I get poison oak really bad,” he said. “I knew there had to be a way to stay out of the patches.” He needed a simple solution, but he didn’t see one in the marketplace. So he began a design for a skidder that would allow him to hook up to a log without getting off the tractor seat. “My first design started with commercial tongs and I welded ‘whiskers’ at the bottom of the hook that would open up on the logs. When I’m cutting firewood, I fall three or four trees at a time,” he explained. “The vast majority of the time, you don’t have to get off the tractor to hook up. This reduces the risk of injury from getting on and off the tractor. It’s much more convenient, and the work goes much faster.” He continued to tinker with ideas and built several prototypes before designing his 3-point-hitch log skidder. I traveled to Repko’s farm to see the skidder in action.

Super Easy Skidder

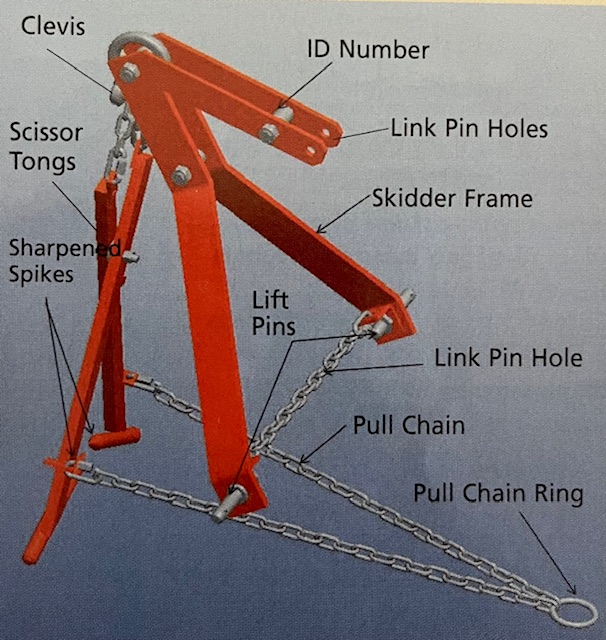

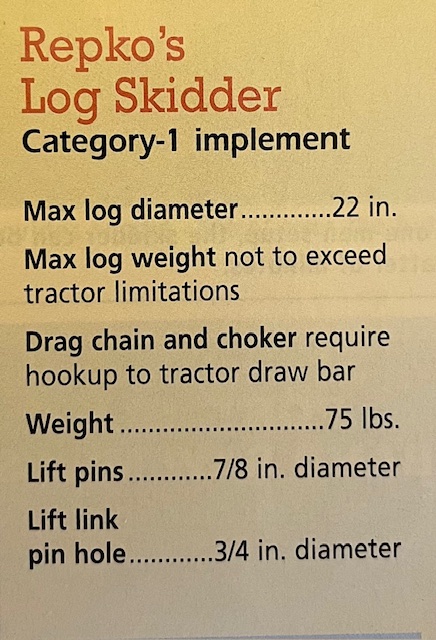

The 3-point-hitch log skidder is designed for operation from a tractor. The attachment enables easy log grabbing right from the operator’s seat. It fits most small to midsize tractors equipped with a category-1 3-point hitch. At 75 pounds, it can be attached by one person in a matter of minutes and will allow an operator to pick up, skid out, and drop logs from 6 to 22 inches in diameter. Once the skidder is attached, the operator backs the tractor over the log end. The log should be as closely aligned to the center of the tractor as possible.

When in proper position, the “whiskers” will automatically contact the log and spread open the tongs, allowing them to settle down along the opposing sides of the log. When the tong points are slightly lower than the widest part of the log, the operator raises the 3-point lift arms to allow the tongs to engage the log. The tongs can effectively grip as long as the tractor is positioned within 30 degrees of alignment with the log.

Once the tongs are engaged, the operator should look to ensure that the pull chain is properly attached to the tractor pull hook and that it is not tangled with the whiskers or ground debris. With the hookup complete, engage the tractor and drag the log to the desired location. To release the log, lower the 3-point hitch to the full down position. The tongs will release when the log is fully resting on the ground and tension removed. The operator then drives forward a short distance (12 to 36 inches) to allow the scissor tongs to clear the log. The 3-point hitch should then be lifted to a reasonable and safe height to prevent the scissor tongs from dragging on the ground. An optional choker could be set during the attachment process; however, the skidder is designed to be used without a choker except in rare instances. Repko warns never to put hands or feet beneath the log while setting the choker. If a choker is being used, ensure that it is properly attached to the tractor hookup. About the only time Repko gets off the tractor is when he’s moving a leaner.

Moving a Leaner

Repko demonstrated the versatility of this simple tool by pulling a leaner out of a dense stand of fir. “A leaner is a typical problem in thinning,” he said. “If you were to hook a choker to the bottom and try to pull it out, as you start pulling, the butt could hit the stump and the tree could flip over on you and ruin your day!” Since he estimates that 7 out of 10 of his firs have some lean, he needed the skidder to safely remove them. “I need to control the direction they come down. So when I come into a stand I think about where I want to fall it. I want it to fall in a direction that gives a good straight path out of the stand. With the skidder, I can just take it where I want it and drop it. I limb it right in the stand so I leave all the debris behind before yarding it out.” Repko said that the skidder is a safe, controlled method for pulling out a leaner because it allows him to totally constrain the butt of the tree. It’s secured, he said, “so it never flips over, it never rolls, it falls exactly the opposite direction of where you’re pulling it.”

Next, he demonstrated use of the skidder for firewood cutting. “In order to save my knees and my chain bar, I hook the skidder onto the center of the log and lift it. While it’s suspended, I can stand upright by the log and limb it and cut it to length without bending over or digging my chain saw in the dirt.” For the demonstration, he suspended a green Douglas fir completely up off the ground in about a minute.

Tractor 101

Repko explained that his skidder was designed to eliminate the risks of flipping the tractor by properly placing the draw bar beneath the center of the axle. “On a tractor you don’t ever want to pull from up high,” he said. “You have to keep the pulling load below the axle on the draw bar. If you weld a hitch eye up high and hang commercial tongs from it, you can flip over in a heartbeat if you’re pulling with a big tractor.” Though such knowledge is “tractor operations 101,” according to Repko, he also verified the forces using computer-aided design (CAD) models. “The forces when you’re-pulling must be below the center of the axle,” he explained. “Everything rotates around that point. If the arm is below that point as you pull, the front end of the tractor will lift. Once you start pulling, the forces pull the tractor front end back down, but depending on the load and forces, there’s still risk of flipping.” The draw bar on Repko’s 3-point skidder is designed to keep the load below the axle, to pull the front end down at all times.

Repko said he designed the skidder using the Pro Engineer CAD program. “I had the idea in my head, so I built a prototype and started using it. When I got the CAD package, I made models that let me analyze the forces. The CAD package pointed out weak spots, so I addressed them by changing some angels and using stronger steel. I discovered that my original lift arms would swing out and the stress would eventually cause them to fail. I added a chain that keeps the arms from swaying out. The chain is more expensive than a solid bar, but it’s a more durable and practical design.” The tongs are made from 1018 cold rolled 1-inch round steel with 1-inch- long sharpened spikes. “It’s so simple that it’s almost maintenance free,” Repko said. It’s powder-coated so it won’t chip and rust. If you’re working with a lot of hard-woods, you may want to sharpen the points on the tongs, but that’s about it!”

Small Business Success

When others took notice of Repko’s skidders, he started manufacturing them for sale. He and his partner (his wife) began exclusively selling them though their website about four years ago. “Last year, I started signing up to present it at various tree schools and logging shows,” he said. “We sold more last year than ever before by letting people see it and use it. Once people see how easy it is, they usually want one!” During my visit to Repko’s property, my partner, who had never operated the skidder, was able to successfully make a good connection and move a log in about two minutes.

In addition to shipping within the continental United States, Repko has shipped skidders to Australia, Italy, France, Canada, Alaska, and has had inquiries from Scandinavia. And, since necessity is the mother of invention, he continues to tinker. Right now, he’s prototyping a heavy-duty game cart with a winch and hand brakes. And he’s building and marketing a drop-on hitch receiver he designed for moving utility and other light trailers around the property. Still, he repeatedly reminded me: “I’m retired!”

Written By

Scottie Barnes author, editor, and is the owner of a small piece of land in western Oregon. She grew up in a timber town and remembers the days of the one-log load.